Zogulitsa

Full granulation ntchito ndi mkulu kupanga bwino

Feteleza Wodzigudubuza Press Granulator

Mafotokozedwe Akatundu

Wodzigudubuza atolankhani granulator amapangidwa ndi sanali kuyanika ndondomeko, granulating kutentha firiji, ndi kupanga nthawi imodzi. Lili ndi makhalidwe a ndalama zochepa, zotsatira zachangu komanso ubwino wachuma. Mapangidwe a makinawa amatengera granulation, kupanga ndi kuyang'ana zonse, zomwe zimapangitsa kuti zikhale ndi maonekedwe okongola, ntchito yosavuta komanso kuchepa kwa mphamvu.

Makinawa amatha kusinthika kuzinthu zopangira, sangangogwiritsidwa ntchito ngati granulation m'mafakitale a feteleza, chakudya ndi mankhwala, komanso amatha kugwiritsa ntchito bwino makamaka pazachilengedwe, zitsulo, malasha, kukonzekera kwachilengedwe, komanso ntchito zoteteza chilengedwe.

Makhalidwe Antchito

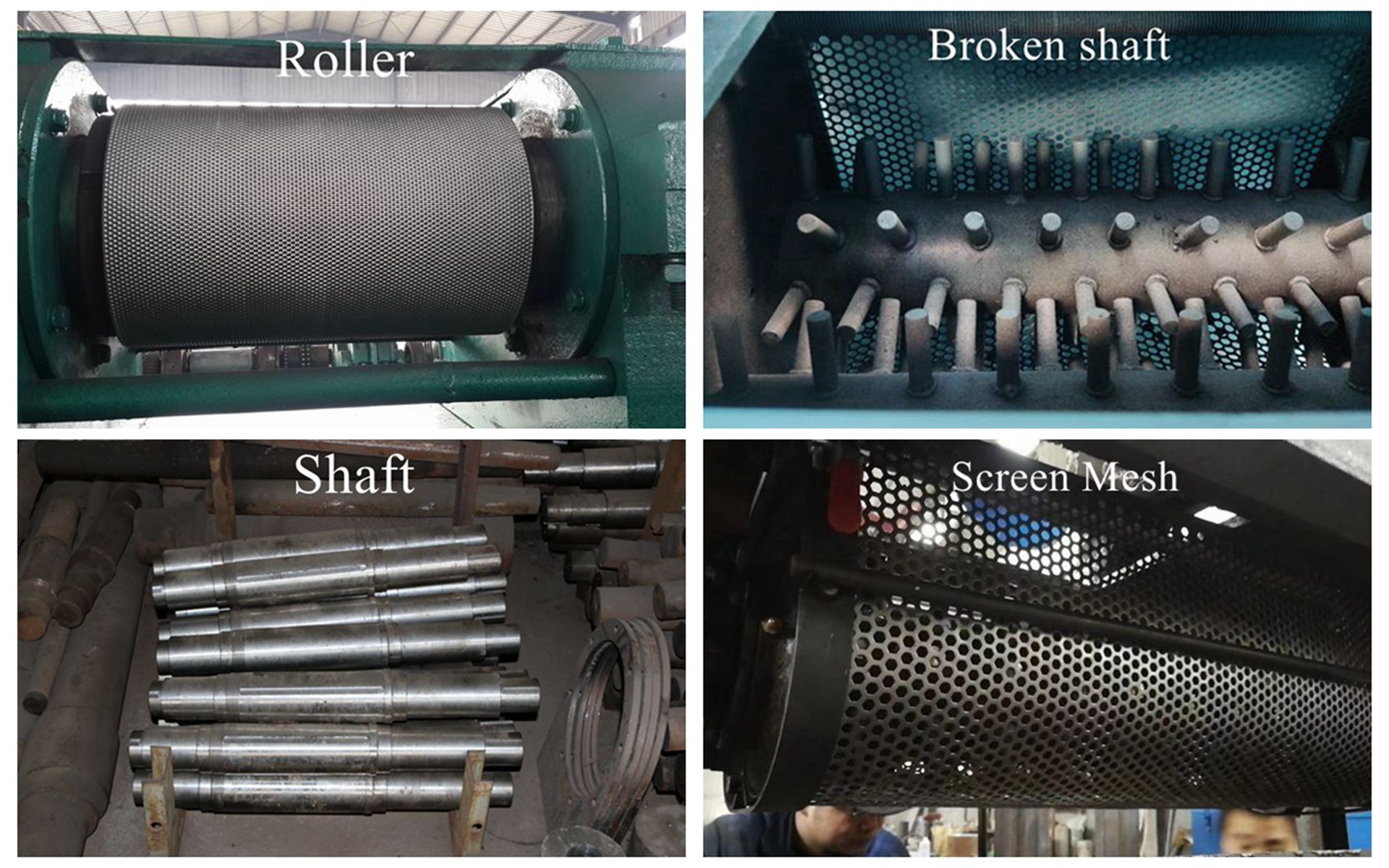

1.The kinetic mphamvu kutengerapo chawonjezeka kwa mipata asanu makona atatu lamba, amene mokwanira anasamutsa galimoto mphamvu ndi kuchepetsa kinetic mphamvu imfa.

2.The reducer amatenga kafukufuku wodziimira yekha ndi chitukuko cha chitukuko cha kampani yathu, ndi kufalikira kwakukulu komanso mphamvu zokhazikika za kinetic.

3.Kupanga njira yodyetsera ndi kusonkhezera kuonetsetsa kuti zinthuzo zikhoza kulowa mu roller kufa mofanana ndi kuteteza pakamwa kudyetsa kutsekereza.

4.Mbali zonse za m'munsi mwa nkhungu zodzigudubuza zili ndi zida zodzitchinjiriza zodzitchinjiriza kuti ziteteze zida kuti zisamamatire pakhungu lodzigudubuza.

Mfundo Yogwirira Ntchito

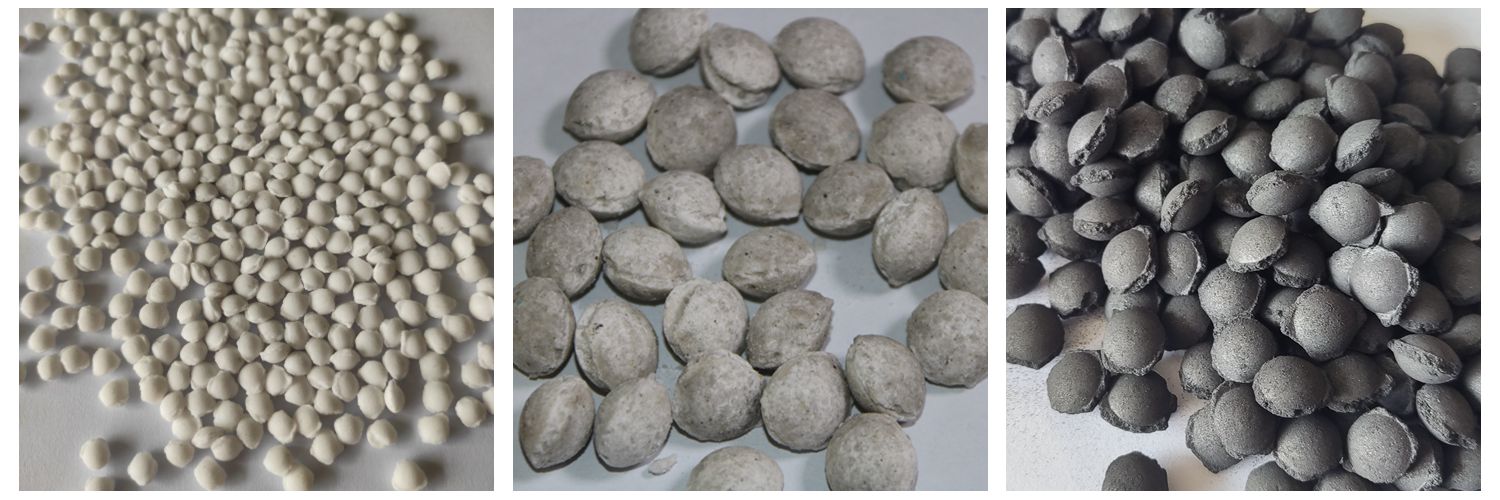

Mndandanda uwu wa granulation wodzigudubuza ndi wa chitsanzo cha extrusion sliding, chomwe mfundo yake yogwirira ntchito ndi: lamba ndi lamba pulley imayendetsedwa ndi galimoto yamagetsi, ndipo imaperekedwa ku shaft yoyendetsa galimoto ndi reducer, ndikugwira ntchito mofanana kudzera muzitsulo zotseguka ndi zopanda pake. Shaft. Zinthuzo zimawonjezedwa kuchokera ku hopper ya chakudya, yotulutsidwa ndi chodzigudubuza, kuchotsedwa ndi kupukutidwa, ndikudutsa muunyolo kupita ku situdiyo yophwanyidwa, komwe kumalizidwa. ma pellets azinthu (mipira) amawonetsedwa ndikulekanitsidwa, kenako zinthuzo zimabwezeretsedwa ndikusakanikirana ndi zida zatsopano za granulation.

Main Technical Parameters

| Chitsanzo | DJJ-Ⅰ-1.0 | DJJ-Ⅰ-2.0 | DJJ-Ⅰ-3.0 | DJJ-Ⅰ-4.0 | DJJ-II-1.0 | DJJ-II-2.0 | DJJ-II-3.0 |

| Mphamvu zopanga (t/h) | 1-1.5 | 1.5-2.5 | 2.5-3.5 | 3.5-4.5 | 1-2 | 1.5-2.5 | 2.5-3.5 |

| Mphamvu | 15kw pa | 18.5kw | 22kw pa | 45kw pa | 15kw pa | 18.5kw | 22kw pa |

| Pressure roller size | Φ150×220 | Φ150×300 | Φ186×300 | Φ300×300 | Φ150×220 | Φ150×300 | Φ186×300 |

| Kudyetsa kukula | ≤0.5mm | ≤0.5mm | ≤0.5mm | ≤0.5mm | ≤0.5mm | ≤0.5mm | ≤0.5mm |

| Anamaliza mankhwala mfundo | Φ2.5-φ10 | Φ2.5-φ10 | Φ2.5-φ20 | Φ2.5-φ30 | Φ2.5-φ10 | Φ2.5-φ20 | Φ2.5-φ20 |

| Mtundu wochepetsera | ZQH350 | ZQH400 | ZQH400 | ZQH500 | cholinga chapadera | cholinga chapadera | cholinga chapadera |

Ntchito Video

Ntchito Project

Chomera cha 1-20tph cha feteleza chokhala ndi makina osindikizira a granulator:

Kutumiza

Phukusi: matabwa phukusi kapena zonse 20GP/40HQ chidebe

Pemphani Mawu

Sankhani chitsanzo ndi malo oda

Sankhani chitsanzo ndikupereka cholinga chogula

Pezani mtengo woyambira

Opanga amatengapo gawo kuti alumikizane ndikudziwitsa ma lo

Kuyendera mbewu

Kalozera wophunzitsira akatswiri, ulendo wobwereza wokhazikika

Saina mgwirizano

Sankhani chitsanzo ndikupereka cholinga chogula

Pezani zotsika mtengo zaulere, chonde lembani izi kuti mutiuze ( zinsinsi, zosatsegulidwa kwa anthu onse)

Ngati muli ndi chidwi ndi zinthu zathu kapena mukufuna kudziwa zambiri, chonde dinani batani loyang'anira kumanja

Pezani mawu

Pezani mawu + 8618937171932

+ 8618937171932